Aizu Momen is a type of cotton textiles woven in Aizu Wakamatsu, a city located in the northeast part of the Japanese Archipelago. Surrounded by mountains, the town gets extremely hot during the summer and equally cold during the winter, with heavy snowfall that often reach up to 1 meter deep. Production of cotton began in various regions in Japan approximately four hundred years ago. Aizu Wakamatsu was one of the places where the cotton production was practiced actively, and the production of cotton textiles concurrently became popular. Since cotton plants prefer a temperate climate, Aizu Wakamatsu is known to be the northern limit for the production of the plant in Japan.

Aizu Momen is a type of cotton textiles woven in Aizu Wakamatsu, a city located in the northeast part of the Japanese Archipelago. Surrounded by mountains, the town gets extremely hot during the summer and equally cold during the winter, with heavy snowfall that often reach up to 1 meter deep. Production of cotton began in various regions in Japan approximately four hundred years ago. Aizu Wakamatsu was one of the places where the cotton production was practiced actively, and the production of cotton textiles concurrently became popular. Since cotton plants prefer a temperate climate, Aizu Wakamatsu is known to be the northern limit for the production of the plant in Japan.

Aizu Momen was mostly used for making working clothes. It is characterized with various patterns of stripes, made with combinations of unique colors. The “stripe” technique was brought in by weavers who were invited into the region. Each area developed a wide variety of Jijima, or local stripes, with different colors and widths of stripes dyed with vegetation unique to each locality. These local stripe patterns were specific enough so that one could identify which village a person lives in from their stripes. Wearing the clothes with jishima pattern woven in also symbolized their pride in the land they live. The record book holds close to 100 patterns of jishima, and those beautiful stripes are the major characteristic for Aizu Momen.

Compared to other cotton textiles, Aizu Momen has higher breathability and moisture retention property. Prior to weaving, the warp is soaked in wheat starch solution to get starched. Weft yarns are then woven in between them, creating fine nodes that keep a layer of air within the textile. The air-involved textile can keep coolness during the summer with high ventilation, and warmth during the winter. It is the textile created by the natural features of the region, and from the necessity in living under the severe climate.

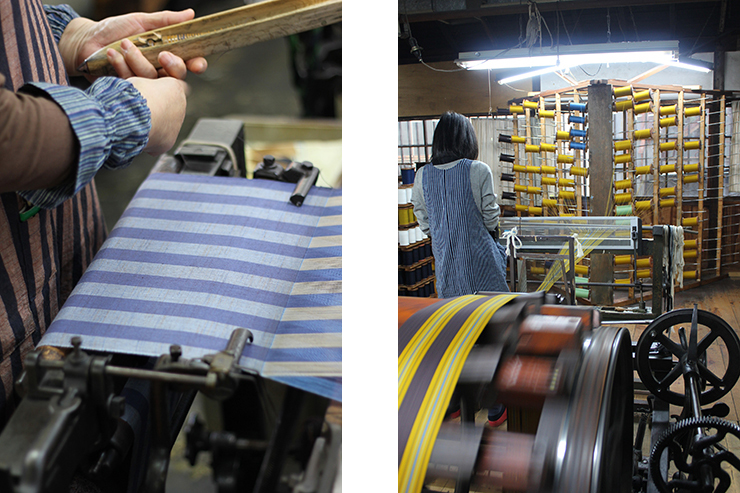

In the corner of vast rice fields, there is a textile factory that has been there for a hundred and twenty years. It is one of the two that still remain operative. In the factory, the automatic looms are still in operation, carefully repaired and parts replaced. These machines were developed by the founder of Toyota Motor, Sakichi Toyoda, prior to his famous automobiles.

The standard width of the woven textile remains 38 cm, just as it was designated back when kimono was worn on daily basis. Within the width, 900 warp yarns are woven in. In the process of seikei (literally, ‘putting warps in order’) prior to setting them on the loom, 900 warp yarns are sorted by colors and sequence of weaving, and wound up on to a huge roll. Weft yarns are wound up on a tool called kuda (literally, ‘tube’) as preparation for weaving. One kuda would have enough string to make textile 70 cm long, and the choice of the color of the weft would have a major effect on the texture and appearance of stripes.

The 900 weft yarns put in order would then put through the part of the loom called sokko (heddle). Each yarn is installed by hand. As the heddle lifts up the warp, another tool called hi (shuttle) containing the kuda with weft yarn inside slides through, and the osa (reed) beats in. Thus, the warp and weft are alternately woven.

When the time comes, fourteen looms lined up in rows start working all at once. 900 warp yarns go up and down, and the weft dashes through between them. The weft shuttles back and forth repeatedly. Soon the continuous accumulation of warp and weft creates beautiful stripes, and a sheet of textile slowly appears.

In the loud noise of machines, female factory workers come and go between looms.

“We listen carefully to the sound of looms and identify the difference, and by doing so we can feel how the looms are working,” they say.

Aizu Momen has been woven by the female workers in between their farm work. Women are still the ones operating the looms today.

The weft runs through between the lifted warps. It goes and comes back, again and again. During this repetitive labor, the weavers seem rather meditative. It may be their time to contemplate on deep thoughts on their daily lives usually put away in the deep end of their mind. They dove quietly into their inner world, as if to slowly sink down into a calm lake. Like prayer, they weave their thoughts together into the textile.

“May this textile help people withstand the heat of summer and endure through the cold of winter.

While listening carefully to the sound of looms, they weave the piece of textile with their thoughts for the family, people, and the land they live in.

- Textile :

- Aizu Momen

- Textile of Okinawa

- Ryukyu Bingata

- Ryukyu Kasuri

- Yuki Tsumugi

- Old textile

- Dyeing :

- Indigo